While researching an alternative to the Atmel 328p for the Pathfinder (compass data logger) project I decided I just had to try out the latest, greatest chip in the Texas Instruments “value line” G series, which is the MSP430G2955. This chip features 56k of flash, 4k of RAM, and more I/O than you can shake a stick at. This chip was only released a few months ago and none of the sources I can access had any stock yet. I’d been using the TI developer web site a lot the past couple years and decided to order a sample part for the first time. TI sent one immediately by FedEx. Hopefully this article will serve as a small, initial thank you. I’ve loved the folks at TI for 35 years since I was part of a company that OEM’d their computer systems. I still have fond memories of visiting the R&D sites in Dallas and Austin.

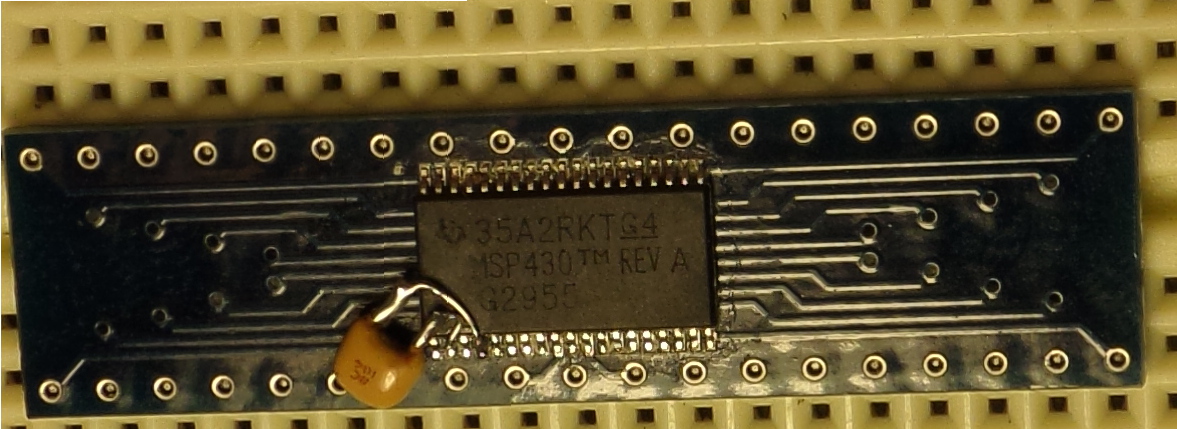

The problem, however, is that the least impractical package this device comes in is a 38 pin TSSOP package with .025″ lead spacing. Notice in the picture above there are four leads in the .1″ spacing between protoboard holes. Notice the bypass cap leads look like the Alaskan pipeline. (I used wire wrap wire to connect to the power and ground pins.) The most pointy soldering iron tip I own looks like the end of an unsharpened pencil in relation to this pin spacing. What to do?

I found a Youtube video (if I can find the URL easily I’ll paste it back into this blurb). It held the big secret: you solder a chip like this and then unsolder the spaces between the pins. Physics won’t allow the solder directly under the pins to be slurped out by braid type solder wick. Wow.

Here’s how to solder a chip like this. I assume you’re very experienced with soldering except for these itty bitty components and that you’re using a temperature controlled, low power iron with a tip so sharp that it’s painful to put your finger on it (when cold). A regular, small chisel tip iron might get the job done with the right (very small) amount of solder on the tip.

- Meticulously clean the board with alcohol

- Apply liquid flux to the pads

- Put the chip in place and slop more flux across two diagonal corners

- Hold the chip EXACTLY right on the pads and touch the two corner pins with an iron holding the merest dab of solder

- Put flux across both rows of pins

- Put a length of very small gauge (e.g. 26 gauge) solder lengthwise across one row of pins, stopping short of the corner you tacked on.

- Run the soldering iron across the pins, melting the solder and going at a speed such that you can see the solder wicking under the pins. IGNORE the fact that you’re soldering multiple pins together into unrecognizable blobs.

- Put flux on some very small solder wick and lay it across a row of pins at a time

- Put the iron across the flux and let it slurp excess solder off the pins a group at a time

- Inspect the soldering with a decent magnifier and convince yourself there’s a nice solder joint under each pad

- Ohm out the connections to confirm everything is right and there are no shorts or opens

That’s it. I couldn’t believe that I could do this right the first time and when my health recovery allows it I’m going to have a blast with this chip. Some back of the envelope calculations suggest I can get the total quiescent current of the logger under a milliampere, so one large (nonmagnetic) Lithium coin cell may get the job done and run the logger for an entire summer of butterfly tracking, with the big flash memory standing in for the SD card used by the current logger.

By the way, the excellent quality DIP adapter came from a firm with a presence in nearby Morrisville, NC called EZ Prototypes. They had to ship my part from Boston but it got here in two days at a very reasonable price. Update September, 2019: This link is no good any more: the domain is no longer registered. Too bad. But anybody unable to find a 38 position adapter and interested could ping me at pete at apexprotofactory dot com about making one, as this is a simple exercise for me now.